Comparison of corrugated kraft paper: choosing the most suitable packaging material

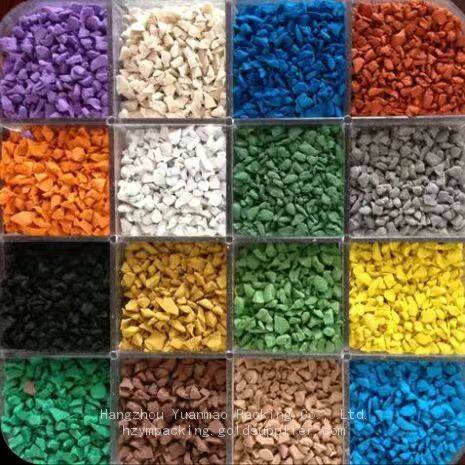

Common 20 kinds of plastic packaging materials use

1、Low density polyethylene (LDPE, LLDPE)

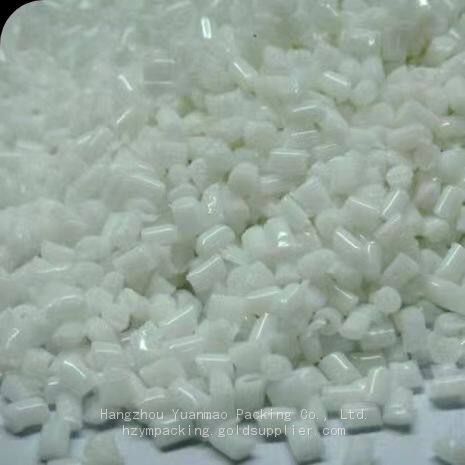

Polyethylene is white waxy solid, translucent, almost odorless and non-toxic. Polyethylene macromolecular chain of good flexibility, it is easy to crystallize, at room temperature polyethylene consists of partially crystallized and partially in the high elastic state of the amorphous body.LDPE

Performance characteristics of low-density polyethylene processing performance, good transparency, but poor airtightness, low tensile strength, and heat-resistant temperature is not high, chemical resistance, solvent resistance is not as high as high-density polyethylene, and easy to absorb the swelling of oil and grease, so that the products are sticky.

Scope of application: Blow-molded bottles, extruded hoses for spices, medicines and other packaging; caps, stoppers and other container accessories; a variety of packaging films, containers and foam cushioning materials.

LLDPE

Performance characteristics impact strength, stress cracking resistance and high density polyethylene is similar to the transparency, hardness and processing performance between high-density and low-density polyethylene. Elongation and puncture resistance are the best among all kinds of polyethylene.

Applicability is particularly suitable for packaging film, its thickness can be 20% thinner than low-density polyethylene, is a very promising plastic packaging materials.

2, high density polyethylene (HDPE) high density polyethylene

Performance characteristics of strength, heat resistance, the highest temperature up to 120 ℃, transparency, elasticity and processing performance is poor, poor gas barrier, low gloss, printing before the need for surface treatment.

Scope of application containers, pallets, large drums for fresh milk, chemical products and other turnover packaging, bottles with yogurt, detergent bleach packaging, caps, stoppers and other container accessories.

3, foamed polyethylene - EPE (commonly known as pearl cotton) is divided into sheets, plates, tubes, rods, and its split slice modeling.

Scope of application is widely used for packaging any shape of goods, especially electronic products such as: computers, TVs, stereos, speakers and other types of electrical appliances anti-static buffer packaging. Pearl cotton is environmentally friendly, characterized by good elasticity and toughness. Can also make life jackets, pontoons, travel bags, hats and so on.

4, polypropylene (PP) polypropylene

Performance characteristics of polypropylene is the lightest of the general-purpose plastics, its heat resistance is the highest of the general-purpose plastics, can be in 100 ℃ ~ 120 ℃ long-term use. High crystallinity, tensile strength and hardness are better than polyethylene, moisture resistance, water resistance and prevention of odor permeability is better, can be heat-sealed. Excellent bending fatigue strength, can withstand 80 ℃ below the acid, alkali, salt solution and most organic solvents such as polypropylene boxes to take advantage of this feature.

Cold resistance, poor aging resistance, poor airtightness, not suitable for use at low temperatures, and susceptible to light, oxygen. It must undergo surface treatment before bonding or printing.

Scope of application is widely used in the production of food, chemical products, cosmetics, food and beverage, beer and other crates, blow-molded bottles for shampoo, cosmetics and other packaging, threaded caps or with hinged packaging, woven bags, and packaging film, packing tape and foam cushioning materials.

5、Polystyrene (PS)

Performance characteristics colorless and transparent, odorless and non-toxic, good coloring and printing, low water absorption, good dimensional stability, rigid and non-extensible. Resistant to organic acids, alkalis, salts, low-grade alcohols and their aqueous solutions, low impact strength, surface hardness is small, easy to scratch and bristle; moisture resistance, heat resistance is poor, susceptible to many hydrocarbons, ketones, fatty acids, etc., the division and softening.

Scope of application is widely used in the production of food, pharmaceuticals and daily necessities and other small packaging containers, such as boxes, cups, etc. and food packaging film. In addition, a large number of foam cushioning materials used in the production of instruments, meters, electrical products, such as cushioning shockproof packaging.

6, polyvinyl chloride (PVC)

Performance characteristics of rigidity and hardness, poor heat resistance, transparency up to 76% to 82%. Mechanical strength, abrasion resistance, excellent pressure resistance, moisture resistance, water resistance and good airtight, can be heat-sealed. Excellent printing performance and flame retardant. Resistant to strong acids, alkalis and non-polar solvents, susceptible to the erosion of polar organic solvents, containing toxic vinyl chloride monomer, and plasticizers, stabilizers, etc. are mostly toxic substances, so the polyvinyl chloride used for food and pharmaceutical packaging should be used for non-toxic additives, and the content of vinyl chloride monomer does not exceed 1ppm.

The scope of application is to make rigid packaging containers, transparent sheets and flexible packaging films. Polyvinyl chloride transparent sheet is thermoformed into various packaging containers, which are used in large quantities for the packaging of food and pharmaceuticals. In addition, polyethylene can also be made into foam and cushioning materials.

7, polyethylene terephthalate (PET)

Performance characteristics of very good mechanical strength, good hardness, abrasion resistance and folding resistance, heat resistance, cold resistance, good moisture resistance, airtightness and excellent prevention of odor permeability, resistance to weak acids, weak bases and most solvents, good oil resistance, suitable for printing, does not tolerate strong alkalis, acids, chlorinated hydrocarbons, etc., also has an erosive effect; easy to static, and there is no appropriate method of preventing static, poor performance of heat sealing The price is expensive.

Scope of application is mainly used for the production of packaging containers and films, because of good airtightness, heat resistance and cold resistance, so polyester film is suitable for frozen food and cooking food packaging. Polyester bottles are used in large quantities for the packaging of beverages.

8, polyvinylidene chloride (PVDC)

Performance characteristics slightly with a light brown tough material, strong crystallinity, water vapor, gas permeability has a very good airtight and moisture resistance. Polyvinylidene chloride has good mechanical strength, resistance to strong acids, alkalis and organic solvents, excellent oil resistance, self-adhesive, difficult to burn and has a spontaneous combustion, poor aging resistance, susceptible to ultraviolet light, easy to decompose out of hydrogen, and its monomers are also toxic. So for food packaging should be strictly controlled quality standards.

9, polyamide (PA)

Performance characteristics of tough, not very transparent horny material, odorless and non-toxic, burning wool burning odor. Strong crystallinity, high melting point, oil resistance, general solvent resistance, excellent mechanical properties. Expansion strength and impact strength is significantly better than the general plastic, good wear resistance, self-lubricating, and has a high resistance to bending fatigue strength, good low temperature resistance, but poor high temperature stability. Airtightness is better than polyethylene and polypropylene, alkali and dilute acid resistance, no static electricity, good printing performance. Strong water absorption, moisture permeability, poor dimensional stability at high temperatures, water absorption makes the airtightness fall sharply, nylon is not resistant to formic acid, phenol and alcohols, concentrated alkali also has an erosive effect on it.

Scope of application is mainly used for flexible packaging of food, especially suitable for greasy food packaging. Nylon containers are also commonly used in chemical reagents and other packaging.

10、Polyvinyl alcohol (PVA)

Performance characteristics generally do not have water resistance, but by heat treatment, aldehyde treatment or the use of appropriate organic substances to make the molecular chain crosslinking and other methods, can make it have water resistance. It has good transparency and toughness, odorless and non-toxic, excellent airtightness and fragrance retention, good mechanical strength, excellent resistance to stress cracking, chemical resistance and oil resistance, no static electricity, good printing performance, and thermal bonding. Water absorption , moisture permeability, susceptible to alcohols, esters and other solvents.

Scope of application for food packaging, water-based polyvinyl alcohol can be used for metered packaging of chemicals and other drugs.

11, ethylene vinyl acetate copolymer (EVA)

Performance characteristics stress cracking resistance, cold resistance, aging resistance and low-temperature heat sealing are better than polyethylene, can withstand the erosion of strong alkali, weak acid, the film's poor slip, easy to stick; moisture-proof than low-density polyethylene is poor, and airtightness is bad; heat resistance is poor; susceptible to strong acids and other organic solvents, can be dissolved in aromatic hydrocarbons or hydrocarbons; poor oil resistance.

Scope of application: It is used to make packaging film, because of its good elasticity, it is suitable for the winding and wrapping of pallets. Because of its excellent low-temperature heat sealing, it is often used as a sealing layer of composite films, but also for the production of pharmaceuticals and food packaging containers.

12、Polycarbonate (PC)

Performance characteristics colorless, transparency as high as 80% to 90%, refractive index of about 1.59, suitable for optical materials, with good moisture resistance and airtightness, excellent fragrance and heat resistance, cold resistance, with outstanding impact toughness, non-notched impact strength is the highest in thermoplastics. Small molding shrinkage, low water absorption, good dimensional stability, no static electricity, excellent insulation properties, resistance to dilute acids, oxidizing agents, reducing agents, salt, aliphatic hydrocarbons, etc., good oil resistance. Easy to produce stress cracking phenomenon; poor bending fatigue strength; poor heat sealing; not resistant to alkali, ketone, aromatic hydrocarbons, in a lot of organic solvents in the steam swelling and lead to stress cracking.

Scope of application is mainly used for electrical insulation materials, mainly used in packaging for food packaging, good abrasion resistance, suitable for hardware, pointed items of packaging.

13、Polyurethane (PU)

Performance characteristics excellent elasticity, density, flexibility, elongation and compression strength in line with the requirements, good chemical stability, resistance to many solvents and oils, abrasion resistance of 20 times greater than natural sponge, excellent insulation, sound insulation, shockproof as well as bonding, the price is higher.

Applicability for precision instruments, valuable instruments, handicrafts and other shockproof packaging or cushioning buffer material.

14、Phenolic Plastic (PF)

Performance characteristics of high mechanical strength, abrasion resistance and excellent electrical insulation properties, high temperature resistance, not easy to deform, resistance to certain dilute acids, good oil resistance, poor elasticity, brittleness, the product color is darker, mostly black or brown, can not get a colorless product, strong alkali and oxidizing acid can decompose it, with a slight toxicity.

Scope of application is widely used as electrical insulation materials. Its application in packaging is mainly used to make bottle caps, boxes and acid-resistant containers for chemical products. Bottle caps made of phenolic plastics can withstand the torque of the capping machine and can be kept sealed for a long time without loosening.

15、Urea-formaldehyde plastic (UF)

Performance characteristics of the surface hardness, has a good gloss and suitable translucent, good coloring, can be made into a variety of good appearance and brightly colored products, not easy to adsorb dust, good electrical insulation, chemical stability, not with any organic solvents, excellent resistance to oil and grease, water resistance is poor, easy to absorb the deformation of the water can not be sterilized with steam, the impact strength is also slightly less than the alkali and strong acid resistance. It is not resistant to alkali and strong acid erosion. Scope of application It is used for making delicate packaging boxes, cosmetic containers and bottle caps. Because in acetic acid or 100 ℃ boiling water immersion, there are free of toxic substances formaldehyde precipitation, so it is not suitable for packaging food.

16、Milamine plastic (MF)

Performance characteristics of high strength, not easy to deform, smooth and hard surface, ceramic-like appearance, odorless and non-toxic, good coloring, can be made into a variety of brightly colored products. Good heat and water resistance, good resistance to boiling water, acid, alkali and grease.

Scope of application price is good, mostly used in the production of food containers, can also be used to make exquisite food packaging containers.

17、PVC Heat Shrinkable Film

PVC heat shrink film, divided into ordinary packaging film, color printing film two kinds. Ordinary packaging film: suitable for all kinds of products and combination of packaging. The product is characterized by: good transparency, strong shrinkage rate, easy to operate. After packing, the products can be sealed against moisture, insulated, bright, strong and beautiful. Color printing film, in addition to a variety of color printing labels, is also suitable for product bottles, box packaging rotary body sealing heat sealing.

18、POF Heat Shrinkable Film

POF shrink bag environmental protection, longitudinal and horizontal shrinkage effect, mainly used for gifts, stationery, small hardware and other lighter items shrink packaging.

19、PET Heat Shrinkable Film

The use of “polyester resin chips” production, is internationally recognized as “environmentally friendly” heat shrink packaging materials. Its technical indicators, physical properties, scope of application and use close to the “PVC” heat shrink film. As people's awareness of environmental protection, domestic products are gradually moving towards the international market demand, “PET” heat shrinkable film is currently the most ideal alternative to “PVC” packaging materials.

20、PE Heat Shrinkable Film

PE heat-shrinkable film is divided into two types: simple type and single piece type, which is suitable for all kinds of products to be packaged by full-automatic machine. The characteristics of the product: good toughness, not easy to break, can replace the carton packaging.

Disclaimer: The content is organized according to the network information, the purpose is to convey more information and sharing, and does not mean to endorse its views or confirm its authenticity, and does not constitute any other recommendation. Only provide a platform for communication, not responsible for its copyright. If it involves copyright infringement, please contact us for timely modification or deletion

Recently Posted

-

Paper price hike. India's multi-region carton mills collectively increased prices by 15%

October 15, 2024Paper price hike. India's multi-region carton mills collectively increased prices by 15% Recently, India's Kerala Co Read More

Read More -

Paper price hike. India's multi-region carton mills collectively increased prices by 15%

October 15, 2024Paper price hike. India's multi-region carton mills collectively increased prices by 15% Recently, India's Kerala Corrugated Box Manufacturers Association (KeCBMA) issued a notice announcing that due to the sharp rise in raw material costs, the price of corrugated cartons will be increased by 15%. The main reason for this price hike is the soaring price of kraft paper. The price of kraft paper, the main raw mateRead More -

Packaging Testing Instruments and Equipment Expert Seminar Successfully Held in Jinan

October 10, 2024Packaging Testing Instruments and Equipment Expert Evaluation and Recommendation Seminar Successfully Held in Jinan In order Read More

Read More -

International Seminar on Green, Intelligent and Active Packaging Standardization Successfully Held

October 10, 2024International Seminar on Green, Intelligent and Active Packaging Standardization Successfully Held in Jinan Read More

Read More